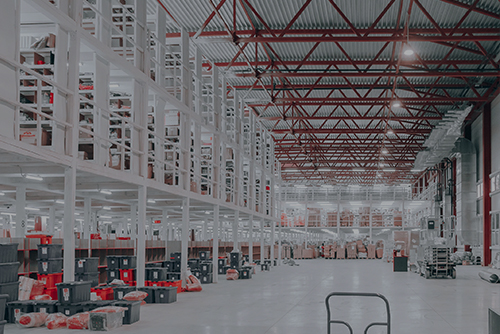

All companies utilize key performance metrics to some degree. For 3PL warehousing in Indianapolis, these metrics provide benchmark standards and allow businesses to identify areas of improvement using collected data. Third-party logistics (3PL) providers and distribution centers benefit significantly from using the right mix of performance metrics. These industries rely on scientific management and streamlined processes to maximize productivity in terms of time, space, and customer satisfaction. Below, we will discuss some of the most critical warehouse metrics that 3PL providers in Indianapolis can use to improve operational efficiency across key supply chain functions.

Unloading: Measuring Efficiency from Dock to Stock

The Unload-to-Stocked Span metric measures the time it takes for a product to reach its designated warehouse position from the moment it arrives by truck. This includes the speed at which trucks are unloaded and how quickly inventory is recorded and stocked. Efficient logistics and supply chain management in Indianapolis depends on minimizing this time to prevent bottlenecks and reduce warehouse congestion. Optimizing unloading efficiency ensures smoother operations, reducing delays in fulfilling customer orders.

Stocking in 3PL Warehousing Indianapolis: Managing Inventory Turnover and Storage Span

The Storage Span metric tracks how long products remain in the warehouse. While overstocking is a concern, knowing how long each product stays in storage helps keep the supply chain on schedule. 3PL Indianapolis providers must balance inventory flow carefully to prevent delays and ensure timely distribution.

Another key metric is Inventory Turnover Rate, which measures how many times per year a warehouse cycles through its entire stock. This is a crucial indicator of warehouse efficiency, helping third-party logistics companies assess the effectiveness of their inventory management strategies.

Order Filling: Accuracy and Speed in Fulfillment

The Order Picking Accuracy metric tracks the percentage of orders fulfilled correctly. 3PL warehousing in Indianapolis depends on high accuracy rates to maintain client satisfaction and reduce costly returns. While speed is essential in warehouse operations, it should not come at the cost of accuracy. By refining order fulfillment processes, 3PL providers can enhance productivity while maintaining precision.

Delivery: Ensuring On-Time, In-Full Shipments

The On-Time in Full (OTIF) Delivery metric measures the portion of orders delivered correctly and on schedule. This is one of the most important performance indicators for logistics and supply chain management in Indianapolis, as it directly impacts customer satisfaction. Implementing automated tracking systems and real-time reporting can help Indianapolis-based 3PL companies improve delivery efficiency.

Enhancing Efficiency in 3PL Warehousing Indianapolis with Key Performance Metrics

Key performance metrics are essential for optimizing warehouse operations and enhancing overall 3PL logistics in Indianapolis. From unloading efficiency to delivery accuracy, these metrics help warehouse managers and third-party logistics providers streamline operations, reduce costs, and improve service levels. By leveraging data-driven insights, 3PL companies in Indianapolis can enhance their competitiveness in an evolving logistics landscape.