Climate Controlled Storage

For over a century, we’ve been providing warehousing services for clients. Headquartered in the heartland of America, our facilities give you a strategic advantage for warehousing and distribution.

CONTROLLED CONDITIONS TO PROTECT YOUR PRODUCTS

Climate control in warehouse storage is, at its essence, all about reducing unpredictability. We provide temperature and humidity-controlled warehouse environments to protect your products or raw materials against the damaging effects of temperature fluctuations.

Climate Controlled Storage is designed to store your products within normal, stable temperature ranges and humidity levels. Climate Controlled is another way of saying “room temperature”, or normal storage conditions between a range of 56°F and 75°F. for products that must avoid hot and cold extremes.

To maintain a normal temperature range, our climate-controlled warehouses depend on industrial air conditioning and heating, to maintain an internal area temperature year round. Our facilities include 24/7 environmental monitoring to ensure internal conditions are always controlled.

Because warehouses are large, open environments with people and goods constantly moving in and out, this naturally results in areas where temperature fluctuations will occur, such as cool spots near loading bays or hot spots where shelves can obstruct airflow.

Climate control in a warehouse helps prevent these environmental discrepancies and produce consistent, controlled conditions throughout all operations. Sometimes referred to as Air Conditioned Warehouses, these storage buildings are specifically designed for items that require a dry environment with a consistent temperature.

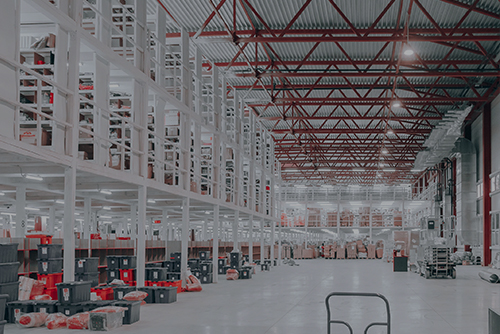

STATE OF THE ART FACILITIES

We offer state of the art warehousing. For your business, this is more than just putting boxes on a shelf. Your business depends on tight integration between internal quality control and tracking systems, our facilities, and the eventual destination.

DTC provides technology that gives you complete control over your inventory. Our warehouse management system is a radio frequency based system that provides you with Internet access to perform real-time functions such as

Smart Warehousing Technology

— IT and ERP Integration

— Monitoring Real-Time Inventory Levels

— eCommerce System Integration

— Scheduling

— 24/7/365 Online Access

— Capturing and Filling Orders

— Generating Reports

— Shipment Tracking

TECHNOLOGY

Your business is only as strong as the decisions you make. Our integrated technology systems give you the data, control, and oversight you need to inform your supply-chain decisions. Whether you’re a manufacturer, supplier, or retailer, our technology gives you complete control over your inventory.

ALL THE SPACE YOU COULD EVER NEED

Warehousing is our bread and butter. For over a century, we’ve been providing warehousing services for clients, with extensive knowledge in warehousing for public, contract, and distribution center management. This expertise, along with our strong network of industry partners, gives our clients access to any size facility you need in whatever location is most advantageous to your business.

We have the resources and expertise to warehouse your products to your most exacting specifications.

Strategic Location

Need a central warehouse and distribution location? DTC is headquartered in the heartland of America, providing you with an ideal location for a Midwest distribution center or part of a broader supply-chain.

Located within 650 miles of over 33% of the US population (1-Day by truck freight), we’re located within a 1-day shipping radius of Chicago, Detroit, Toronto, Indianapolis, Atlanta, Louisville, Memphis, Milwaukee, Nashville, Cleveland, Kansas City, St. Louis, Cincinnati, and Pittsburgh.

Positioned just 70 miles from FedEx’s largest hub in the nation, and less than 200 miles from UPS’s Worldwide air hub in Louisville and DHL’s International air hub near Cincinnati.

Extended Network

We offer multiple warehouse facilities, backed by comprehensive logistics solutions. From product manufacturers, retailers, and food and beverage distributors, pharmaceuticals, plastics, paper and digital media packaging industries, our centralized warehouse facilities offer features and services to meet your warehousing needs.

Our logistics specialists can help decide which mode of transportation is right for your product. This expertise, along with our strong network of industry partners, gives our clients access to any size facility you need in whatever location is most advantageous to your business. Understanding your business and the capability to adapt and respond to your needs sets Distributor’s Terminal apart.

Value Added Services

Let us handle the hard work. We offer a complete range of value-added services for your fulfillment needs, including pre-assembling equipment, adding labels to textile products and stocking display units. We can take care of everything.

Whether your orders are large or small, our sophisticated warehouse management system efficiently tracks inventory, prepares shipping lists and creates invoices to help expedite the order fulfillment process, ensuring order accuracy and timely delivery. Whatever solution you need, the Distributors Terminal logistics specialists are ready to deliver the perfect suite of third-party logistics products and services, including the following specialized services:

Scanning

Our barcoding/serial scanning system tracks your inventory, giving you accountability, oversight, and management of inventory levels at our facilities.

Quality Control

By tracking product rotation and shelf life of your products, we can assist with quality control of your inventory to meet your quality requirements.

Cross Docking

With cross docking, products are received, processed, and shipped in an unbroken sequence, eliminating or minimizing inventory storage needs.

Kitting

Kitting involves pre-assembling individual SKUs into new kits that are ready to ship out right away. Our kitting services make it easier to fulfill customer orders.

Labeling

Your shipment, branded for you. Outsourcing your custom labeling to us offers increased flexibility over your inventory and can help lower your total cost.

Repackaging

Leave the labor-intensive work to us. We employ customized processes to simplify and streamline Pick-and-Pack packaging/repackaging for you.

Order Fulfillment

From confirming orders, customizing packaging, to order distribution and shipping, we’ve got the experience to handle fulfillment of your product.

Returns Management

Our reverse logistics systems handle your product returns and recalls. We can streamline operations by managing return flows into our warehouses.

Reporting

We bring visibility to your inventory. We give you access to real-time data and reporting to help better support your logistics and decision making processes.

Our Facilities

DTC WAREHOUSING

All the space you could ever need

For over a century, we have been providing warehousing services for clients, with extensive knowledge in warehousing for public, contract and distribution center management. This expertise, along with our strong network of industry connections, enables us to provide access to any size facility you need in whatever location is most advantageous to your business.

With multiple facilities supported by comprehensive logistics solutions, we offer specialized storage services including food grade storage, climate-controlled storage, cold storage, and ambient storage.

CLIMATE CONTROLLED

Consistency and control in your storage

We provide temperature and humidity-controlled warehouse environments to protect your products or raw materials against the damaging effects of temperature fluctuations. Climate control in warehouse storage is, at its essence, all about reducing unpredictability. A warehouse is a large, open environment filled with large shelves and racks with people and goods constantly moving in and out. This naturally results in areas where temperature fluctuations will occur, such as cool spots near loading bays or hot spots where shelves can obstruct airflow. Climate control in a warehouse helps prevent these environmental discrepancies and produce consistent, controlled conditions throughout all operations.

FOOD GRADE STORAGE

FDA Registered & AIB Superior Rated

Registered with the FDA, our Food Grade certified warehouse has maintained a Superior Rating with the American Institute of Baking (AIB) since 2009. This certification provides assurance that our facility is maintained to the highest standards of quality, cleanliness and food safety for customers with food service and dry product storage needs. Any logistics business that operates food grade warehousing must follow the regulations set out by the Food and Drug Administration, a government body that regulates the treatment and condition of food products. The FDA has regulations in place for everything from refrigerated storage in warehouse facilities to the supply-chain management. The logistics management team of every facility is responsible for quality food storage, including registration, prevention plans, inspections, recalls, and staying current with all FDA regulatory guidelines.

AMBIENT WAREHOUSING

Storage and solutions with smart technology

Ambient Storage is for storing goods that do not have temperature or humidity control needs. The majority of items are stored here (with the exception of foods and perishables). We offer a full range of services to support ambient warehousing, including Complete Stock Management and Reconciliation, Racked and Bulk Storage, Import/Export Containers Loading/Unloading, Cross Docking, Pallet and Case Picking, Full Transport Management, Real Time Stock Reports, Quality Control, Ambient Distressed Load Management, Full Traceability, ad Digital Based Ordering.

Build-to-Suit (BTS)

Maximize your capacity, minimize your costs

Your warehouse, customized to your requirements. We work to outline your specific needs, develop a plan that meets your needs, then provide blueprints for your approval before construction begins.

We coordinate the major factors that must be considered in the cost of the build-out, including lighting, dock equipment, expandability, storage requirements, safety, and market timing. A build-to-suit strategy can help you support long-term growth goals and needs, and costs saved can be reinvested in core areas of your operation. In such developments there is no requirement of development expertise and the capital required is minimal.

WAREHOUSING NETWORK

Efficiency and flexibility, wherever you need it

Get the space you need, where you need it. Our warehouse network is nationwide, with the locations and services you need so you can tap into available space. Every warehouse is qualified before it can be listed—ensuring services and standards meet our requirements, and yours. Warehouse providers in our network use our technology, so you can seamlessly work with any provider across the network. We monitor warehouse performance to ensure operations are always running smoothly and disruptions don’t get in the way of your business.

A CENTURY OF SERVICE

It takes great service to build a company that can last. Distributors Terminal Corporation (DTC) has lasted for over 100 years, continuously managed and operated by the Hendricks family for more than four decades. We’re extremely proud of our longevity and look forward to the next century of service.

The Longview

HOW WE SEE THE WORLD

We take the time to learn your business. That kind of service and insight is what sets us apart. Understanding your needs and the capability to adapt and respond to change is why clients depend on us year after year.